Concept¶

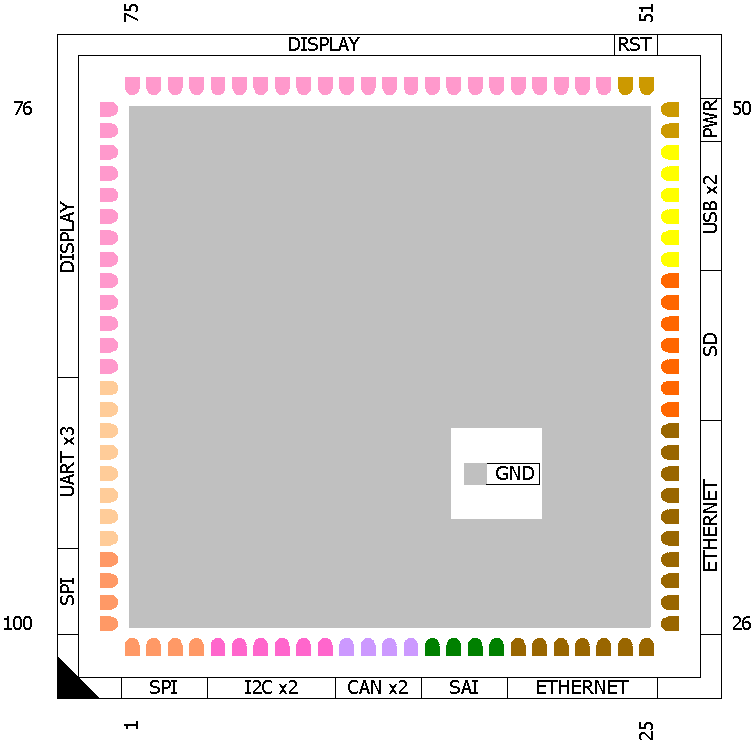

The QS series is a QFN style solder-down Computer on Module. It integrates all the core components such as processor, memory and power supply on a small square size of 27mm (QS) or 29mm (QSX) at a maximum overall mounting height below 3mm, soldered onto an application specific carrier board. Its QFN type lead style has a 1mm pitch with 100 (QS) or 108 (QSX) pads. The central ground pad additionally acts as thermal pad.

Unique Features¶

Since industrial applications lead to faster, higher integrated and lower power electronic circuits with a smaller formfactor, the PCB layout becomes more and more important. With a good layout many EMI problems can be minimized to meet the required specifications. It’s not only the pinout which should lead to an easy wiring without the need for crossings. It has also to provide a proper solution for the signal path back to the module. If this return path, mostly the ground plane, cannot be connected near the signal pin, the return current has to take another way and this may result in a loop area.

With the special design of KaRo’s QS Series you profit from different advantages.

Large ground pad on the bottom side makes a defined ground plane connection available for all signals.

The pinout leads to an easy wiring without crossings.

Ground will be connected near the signal pin to avoid loop areas.

High speed signals can be routed on the top layer at a defined impedance.

Ground pad holds the component at a defined height during soldering.

EMC Quality by Design¶

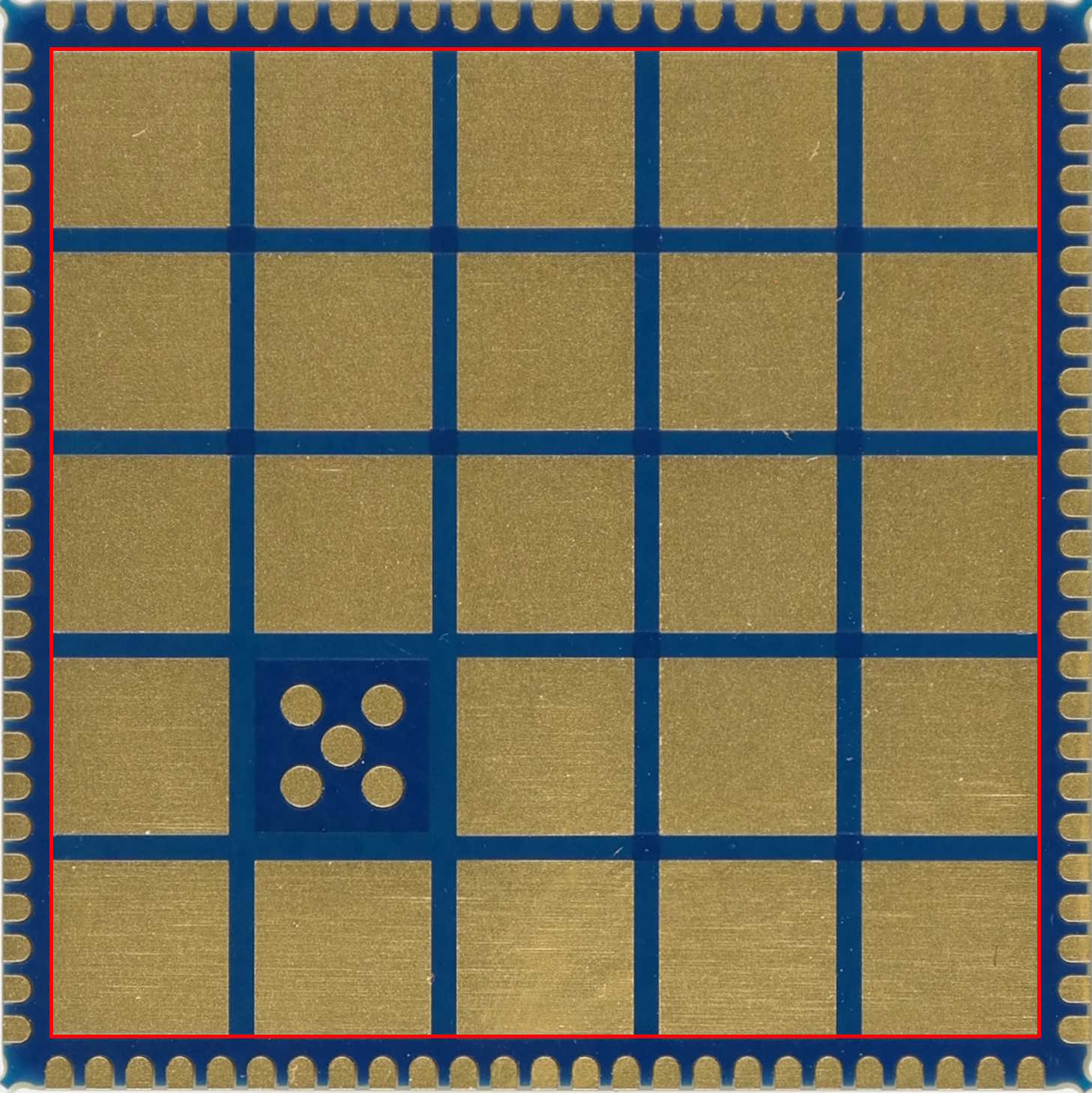

29mm QSX bottom view¶

27mm QS bottom view¶

The reason PCB layout becomes more and more important is because of the trend to faster, higher integrated, smaller formfactors, and lower power electronic circuits. The higher the switching frequencies are, the more radiation may occur on a PCB. With good layout, many EMI problems can be minimized to meet the required specifications.

When a module or component is used in a design, the supplier specifies the basis for such a layout. It‘s not only the pinout which should lead to an easy wiring without the need for crossings. He also has to provide a proper solution for the signal path back to the module. If this return path, mostly the ground plane, cannot be connected near the signal pin, the return current has to take another way and this may result in a loop area. The larger the area, the more radiation and EMI problems may occur.

Ka-Ro QS modules uses a large ground pad on the bottom side. With this a defined ground plane connection is available for all signals. In addition to have a good return path for all signals this large ground pad can be used for cooling.

Advanced Soldering¶

Using a large solder pad underneath the component has not only electrical and thermal advantages. It is also used to hold the component at a defined height during soldering, without the solder being compressed by the weight of the components, which could result in short circuits.

27mm QS - 29mm QSX

QSX is a QS module that has been enlarged by 1mm all around.

The size is hereby increased from 27mm square to 29mm square.

In each corner this gives additional space for a total of 8 further pads which are used for PCIe and USB3.

The inner 27mm x 27mm QS area remains identical providing full compatibility.

Standard Pinout¶

QS Pinout¶

QSX Pinout¶

Pins |

Funktion |

QSMP |

QS8M |

QSXM |

QSXP |

|---|---|---|---|---|---|

1-4 |

X |

X |

X |

X |

|

5-10 |

X |

X |

X |

X |

|

11-14 |

X |

X |

|||

19-35 |

X |

X |

X |

X |

|

36-39 |

X |

X |

X |

X |

|

43-48 |

X |

X |

X |

X |

|

49-52 |

X |

X |

X |

X |

|

53-76 |

X |

||||

53-72 |

X |

X |

X |

||

77-78 |

X |

X |

X |

X |

|

79-88 |

X |

X |

X |

X |

|

89-96 |

X |

X |

X |

X |

|

97-100 |

X |

X |

X |

X |

|

1A,75A,76A,100A |

X |

X |

|||

25A,26A,50A,51A |

X |

Layout Guidelines¶

Land pattern¶

100 pin QS Land Pattern¶

100 pin Common Land Pattern¶

108 pin QSX Land Pattern¶

The five 1mm pads in the square GND pad cutout can be omitted.

Solder Mask¶

QSX Solder Mask¶

QS Solder Mask¶

The ground pad solder mask on the bottom side of the QS module is divided into sections.

GND Vias¶

If the via holes used on the application board have a diameter larger than 0.3 mm, it is recommended to mask the via holes to prevent solder wicking through the via holes. Solders have a habit of filling holes and leaving voids in the thermal pad solder junction, as well as forming solder balls on the other side of the application board which can in some cases be problematic. The 0.7mm wide solder mask stripes can be used to arrange the vias.

Soldering Recommendations¶

Ka-Ro QS modules are compatible with the industrial standard reflow profile for Pb-free solder according to IPC/JEDEC J-STD-020. Ka-Ro will give following recommendations for soldering the module to ensure reliable solder joint and operation of the module after soldering. Since the profile used is process and layout dependent, the optimum profile should be studied case by case. Thus following recommendations should be taken as a starting point guide.

Refer to technical documentations of particular solder paste for reflow profile configurations.

Avoid using more than one flow / Only one reflow cycle is allowed.

A 120μm stencil thickness is recommended.

Aperture size of the stencil should be 1:1 with the pad size.

A low residue, “no clean” solder paste should be used due to low mounted height of the component.

Recommended stencil design¶

QSX stencil design¶

QS stencil design¶

Solder Paste¶

Voiding is a topic for many electronics manufacturers. The proposed stencil design provides gas escape routes during soldering to reduce voiding.

However, the result depends on many factors. A good overview can be found on this page:

https://fctsolder.com/solder-voiding/

Low voiding solder paste is available from many suppliers. Some examples:

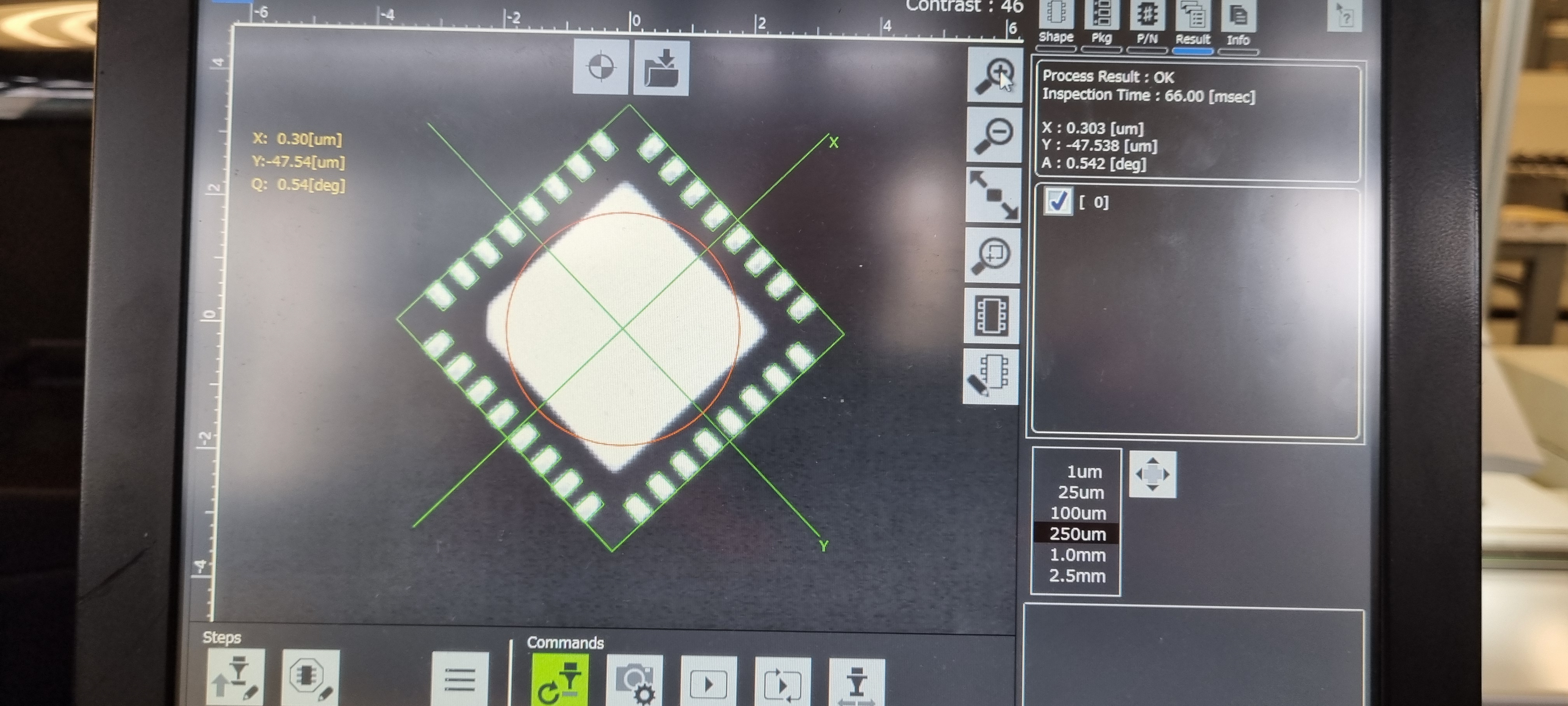

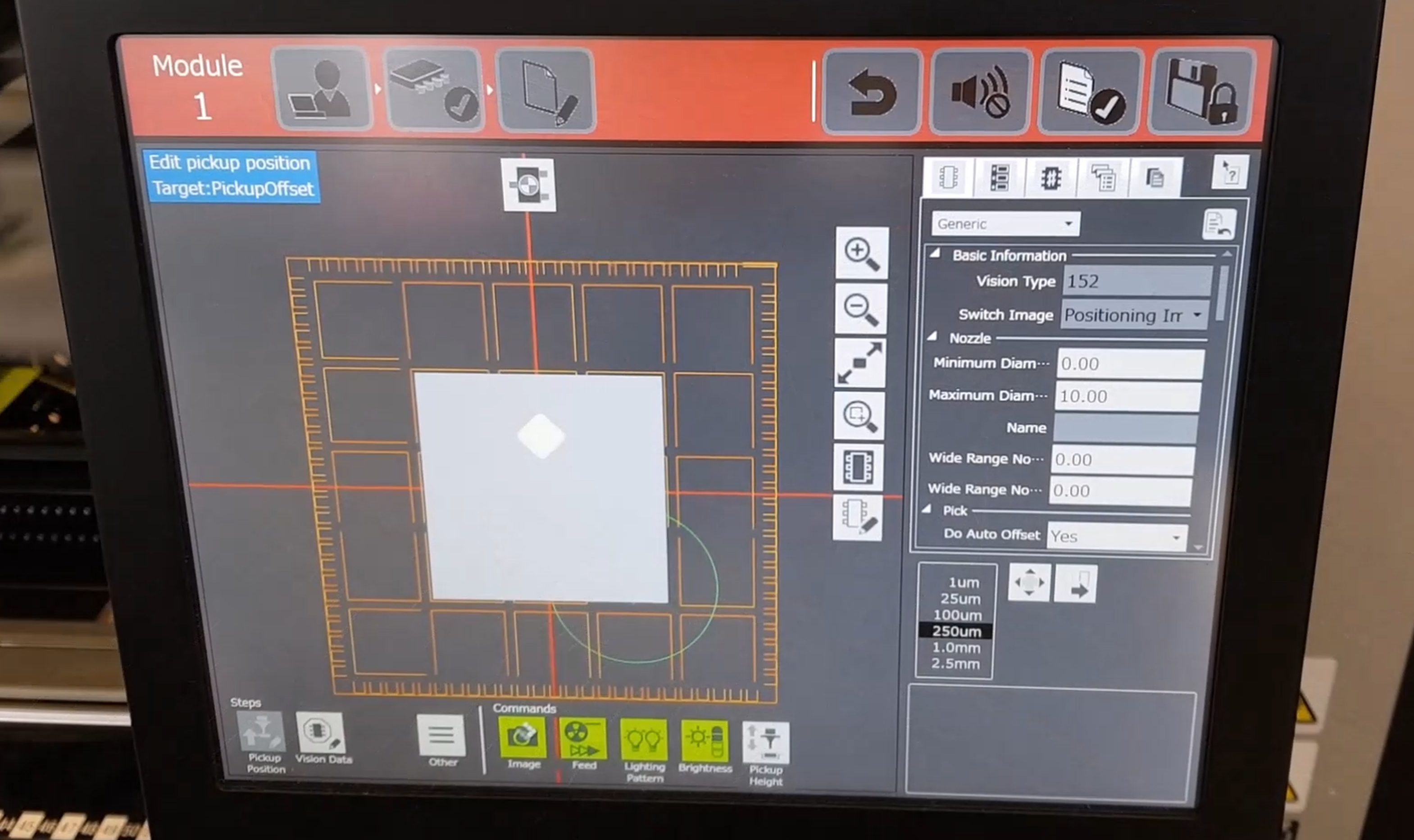

Pick and Place¶

Each part picked is analysed by the vision system prior to placement to ensure that all programmed part dimensions match. It is important that each part is programmed with the correct tolerance parameters so that the machine can detect if an incorrect or mis-orientated part has been loaded and also that acceptable parts are not rejected.

The outer contour of the QS module and the pads on the outer edge of the module are not suitable for this purpose. Due to the manufacturing process, there are certain tolerances for milling the outer contour. As a result, the length of the pads along the outer contour is not always the same.

Due to the panel construction and separation, there may be slight protrusions at the corners.

The large square pads should be used for QS modules to determine the center point and alignment of the module.

Pick offset¶

QS modules cannot be picked in the center. Depending on the QS module, an offset to a suitable surface must be determined.

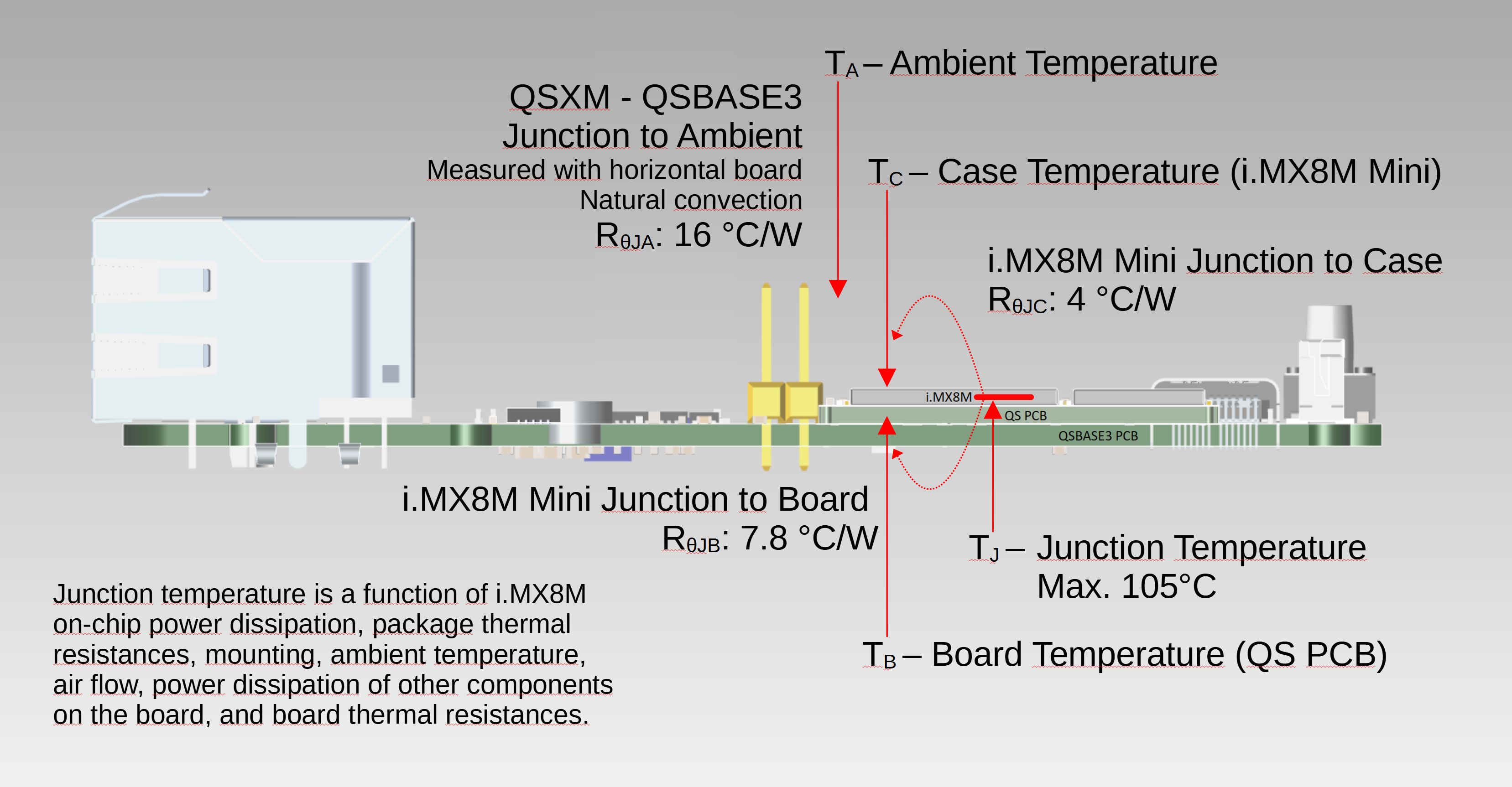

Thermal Considerations¶

The QS module consume more than 1 W of DC power. In any application where high ambient temperatures for more than a few seconds can occur, it is important that a sufficient cooling surface is provided to dissipate the heat. The thermal pad at the bottom of the module must be connected to the application board ground planes by soldering. The application board should provide a number of vias under and around the pad to conduct the produced heat to the board ground planes, and preferably to a copper surface on the other side of the board in order to conduct and spread the heat. The module internal thermal resistance should in most cases be negligible compared to the thermal resistance from the module into air, and common equations for surface area required for cooling can be used to estimate the temperature rise of the module. Only copper planes on the circuit board surfaces with a solid thermal connection to the module ground pad will dissipate heat. For an application with high load the maximum allowed ambient temperature should be reduced due to inherent heating of the module, especially with small fully plastic enclosed applications where heat transfer to ambient air is low due to low thermal conductivity of plastic. The module measured on the evaluation board exhibits a temperature rise of about 20°C above ambient temperature. An insufficiently cooled module will rapidly heat beyond operating range in ambient room temperature.

The package thermal properties can be found in the processor’s data sheet.

Processor |

RθJB |

RθJC |

|---|---|---|

i.MX93 |

6.4 °C/W |

|

i.MX8M Mini |

7.8 °C/W |

4 °C/W |

i.MX8M Nano |

7.8 °C/W |

4 °C/W |

i.MX8M Plus |

0.24 °C/W |

|

STM32MP1 |

20.5 °C/W |

10 °C/W |

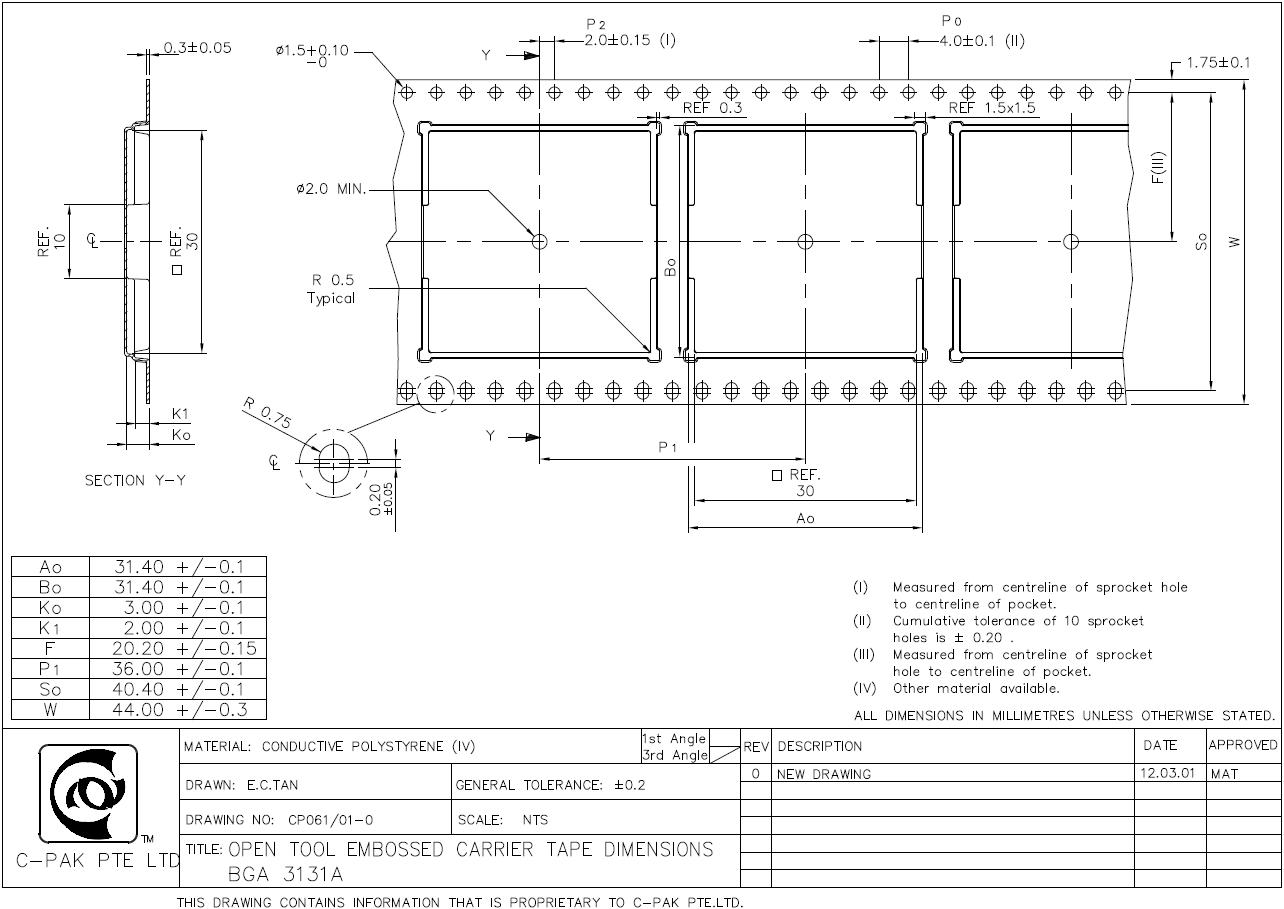

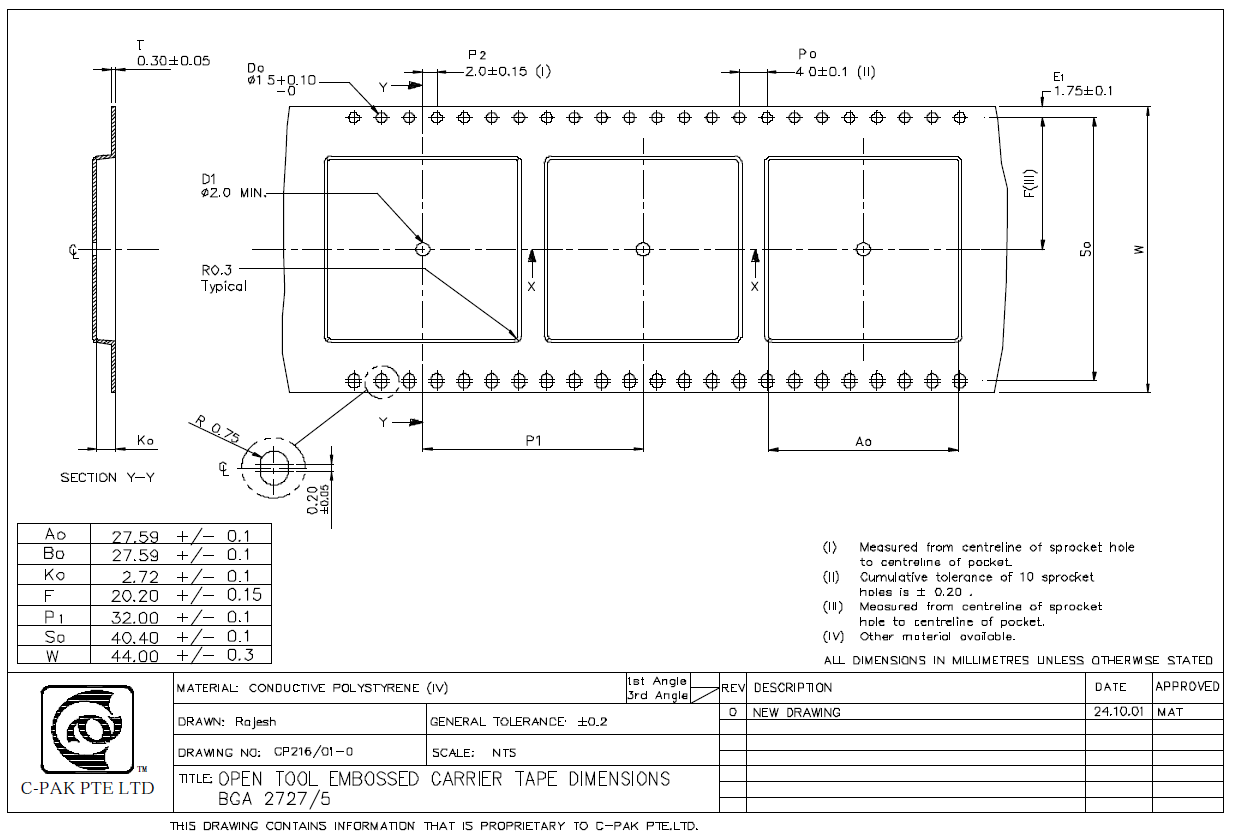

Packaging¶

27mm QS 500 PCS REEL

29mm QSX 500 PCS REEL